cement raw materials processing plant

Analysis of material flow and consumption in cement

2016年1月20日 In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system. 2.48 t, 4.69 t, and 3.41 t of materials are required to produce a ton of the product in raw

Digitization and the future of the cement plant McKinsey

2020年9月16日 Can a fully integrated manufacturing process that has raw material–based production generate higher margins? The COVID-19 crisis has forced cement companies

Cement Production an overview ScienceDirect Topics

Cement production processes can be categorized as dry, semidry, semiwet, and wet processes depending on the handling of raw material before being fed to the rotary kiln.

进一步探索(PDF) Cement Manufacturing ResearchGateCement production global 2022 Statista

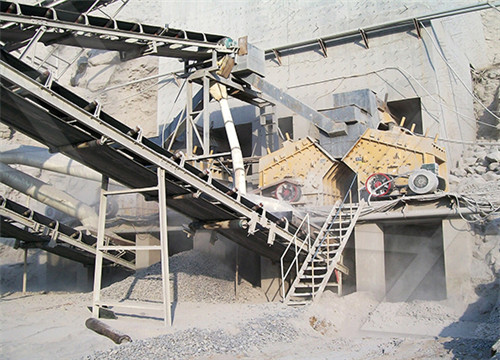

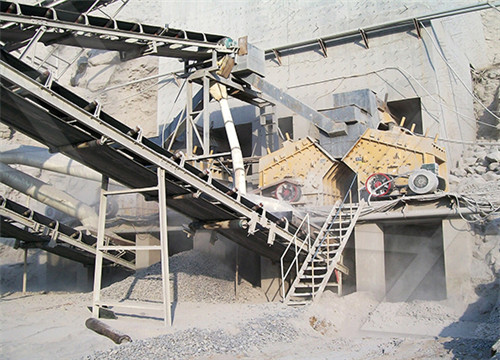

Cement Quarrying, Blasting, Beneficiation, and Grinding

Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting

A Review on Pyroprocessing Techniques for

2020年2月9日 The use of self-calcining materials to make cement can be a welcome venture in such cases where the cement raw materials are

作者: Protus Nalobile, Jackson Muthengia Wachira, Joseph Karanja Thiong’o, Joseph Mwiti Marangu

Cement Plant an overview ScienceDirect Topics

96 行 Fabrizio Bezzo, in Computer Aided Chemical Engineering, 2022 1 Introduction Cement plants, steel mills and refineries are responsible for a significant share of carbon

[PDF]

11.6 Portland Cement Manufacturing US EPA

1971年8月17日 The initial production step in portland cement manufacturing is raw materials acquisition.Calcium, the element of highest concentration in portland cement, is

Environmental impact of cement production and

2022年1月1日 Abstract. This stone reviews the impact of cement industry towards the global environment and solutions to the problem. The increasing harvesting of raw

[PDF]

CEMENT RAW MATERIALS International Cement Review

2013年6月9日 Contents BRITISH GEOLOGICAL SURVEY 1.1 Definition and mineralogy Cement is a manufactured product made by blending different raw materials and firing

Raw materials for cement manufacturing Cement Plant

Limestone: Common forms of calcium carbonate used as raw material for cement manufacturing are limestone and chalk.Limestone is of predominantly fine grained

Analysis of material flow and consumption in cement

2016年1月20日 The material flow route for a cement plant was obtained. • Three mass balances for three cement production stages were established. • Each ton of products requires 2.48, 4.69, and 3.41 t of materials in three stages. • Waste gas recycling rate in clinker production is higher than in other stages. •

Digitization and the future of the cement plant McKinsey

2020年9月16日 According to our analyses, the cement plant of the future could reduce emissions by up to 75 percent by 2050 compared with 2017. Around 20 percent will come from operational advances, such as energy-efficiency measures and clinker substitution. An additional 10 percent will come from alternative fuels—however, the availability of

Environmental impact of cement production and

2022年1月1日 This stone reviews the impact of cement industry towards the global environment and solutions to the problem. The increasing harvesting of raw materials for mounting cement manufacturing causes reduction in quantity of the non-renewable resources such as limestone. The activities linked to harvesting of the resources from

[PDF]

GCCA Sustainability Guidelines for co-processing fuels

2019年10月28日 These guidelines for co-processing of fuels and raw materials in cement manufacturing are part of a package of guidelines developed to support compliance with the GCCA Sustainability Charter 1. The GCCA Sustainability Charter has identified five key pillars which encompass the sustainability issues for the cement and concrete sector:

Cement Plant an overview ScienceDirect Topics

Fabrizio Bezzo, in Computer Aided Chemical Engineering, 2022 1 Introduction Cement plants, steel mills and refineries are responsible for a significant share of carbon dioxide (CO2) emissions ( EEA, 2020 ), which are among the greenhouse gases responsible for the global threat of climate change.

Analysis of material flow and consumption in cement

2016年1月20日 The results show that approximately 2.48 t, 4.69 t, and 3.41 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages, and their waste rates are 63.31%, 74.12%, and 78.89%, respectively. The recycling rate of wastes during clinker production is remarkably higher

[PDF]

11.6 Portland Cement Manufacturing US EPA

1971年8月17日 The initial production step in portland cement manufacturing is raw materials acquisition.Calcium, the element of highest concentration in portland cement, is obtained from a variety ofcalcareous raw materials, including limestone, chalk, marl, sea shells, aragonite, and an impurelimestone known as "natural cement rock".

Advanced analyses of solid waste raw materials from

2019年4月1日 1. Introduction The Egyptian cement market is known to be one of the biggest in the globe including twenty-one cement producers operate twenty-four plants. The cement industry is one of the most important economic drivers in Egypt's economy. Suez Cement Group of Companies (SCGC) is one of the oldest cement producers in Egypt.

Raw materials for cement manufacturing Cement Plant

Limestone: Common forms of calcium carbonate used as raw material for cement manufacturing are limestone and chalk.Limestone is of predominantly fine grained crystalline structure, its hardness is between 1.8 to 3.0 of the Mohs scale of hardness and specific gravity 2. To 2.8.

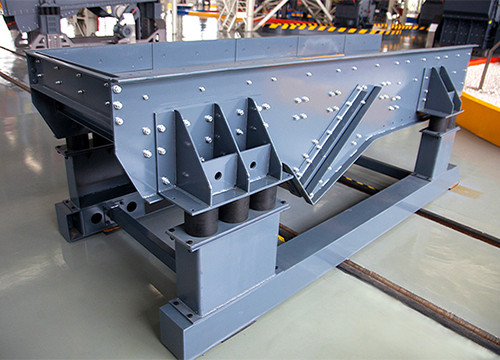

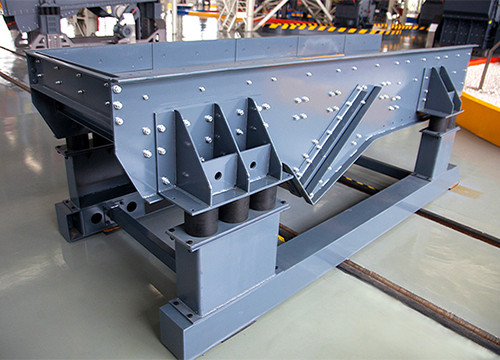

Preparation Of Cement Raw Material Cement

The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing. Crushing: the limestone and other materials are crushed into small pieces by cement crusher,

Analysis of material flow and consumption in cement

2016年1月20日 The material flow route for a cement plant was obtained. • Three mass balances for three cement production stages were established. • Each ton of products requires 2.48, 4.69, and 3.41 t of materials in three stages. • Waste gas recycling rate in clinker production is higher than in other stages. •

Digitization and the future of the cement plant McKinsey

2020年9月16日 Today’s cement plant This future is not far off. Our analysis shows that pursuing digitization and sustainability levers are key to significantly boosting productivity and efficiency of a typical cement plant (Exhibit 1).

Clay calcination technology: state-of-the-art review by the

2021年12月20日 LOI is a well-known indicator in cement plants and its use for calcination of clay is direct . The calibration of the LOI on a performance-based approach makes this indicator valuable. The conditions of calcination giving the highest strength can be targeted in terms of LOI. Emissions from transport of the raw materials to the processing

[PDF]

GCCA Sustainability Guidelines for co-processing fuels

2019年10月28日 These guidelines for co-processing of fuels and raw materials in cement manufacturing are part of a package of guidelines developed to support compliance with the GCCA Sustainability Charter 1. The GCCA Sustainability Charter has identified five key pillars which encompass the sustainability issues for the cement and concrete sector:

Analysis of material flow and consumption in cement

2016年1月20日 The results show that approximately 2.48 t, 4.69 t, and 3.41 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages, and their waste rates are 63.31%, 74.12%, and 78.89%, respectively. The recycling rate of wastes during clinker production is remarkably higher

[PDF]

11.6 Portland Cement Manufacturing US EPA

1971年8月17日 The initial production step in portland cement manufacturing is raw materials acquisition.Calcium, the element of highest concentration in portland cement, is obtained from a variety ofcalcareous raw materials, including limestone, chalk, marl, sea shells, aragonite, and an impurelimestone known as "natural cement rock".

Advanced analyses of solid waste raw materials from

2019年4月1日 1. Introduction The Egyptian cement market is known to be one of the biggest in the globe including twenty-one cement producers operate twenty-four plants. The cement industry is one of the most important economic drivers in Egypt's economy. Suez Cement Group of Companies (SCGC) is one of the oldest cement producers in Egypt.

Parametric Studies of Cement Production

The cement manufacturing process starts by handling a mix of raw materials: (i) naturally occurring limestone, which is the source of calcium, (ii) clay minerals and (iii) sand, which are the sources of silicon and

Cement Quarrying, Blasting, Beneficiation, and Grinding

Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting

A Review on Pyroprocessing Techniques for

2020年2月9日 The use of self-calcining materials to make cement can be a welcome venture in such cases where the cement raw materials are

Cement Plant an overview ScienceDirect Topics

96 行 Fabrizio Bezzo, in Computer Aided Chemical Engineering, 2022 1 Introduction Cement plants, steel mills and refineries are responsible for a significant share of carbon

11.6 Portland Cement Manufacturing US EPA

1971年8月17日 The initial production step in portland cement manufacturing is raw materials acquisition.Calcium, the element of highest concentration in portland cement, is

Environmental impact of cement production and

2022年1月1日 Abstract. This stone reviews the impact of cement industry towards the global environment and solutions to the problem. The increasing harvesting of raw

CEMENT RAW MATERIALS International Cement Review

2013年6月9日 Contents BRITISH GEOLOGICAL SURVEY 1.1 Definition and mineralogy Cement is a manufactured product made by blending different raw materials and firing

Raw materials for cement manufacturing Cement Plant

Limestone: Common forms of calcium carbonate used as raw material for cement manufacturing are limestone and chalk.Limestone is of predominantly fine grained

Analysis of material flow and consumption in cement

2016年1月20日 The material flow route for a cement plant was obtained. • Three mass balances for three cement production stages were established. • Each ton of products requires 2.48, 4.69, and 3.41 t of materials in three stages. • Waste gas recycling rate in clinker production is higher than in other stages. •

Digitization and the future of the cement plant McKinsey

2020年9月16日 According to our analyses, the cement plant of the future could reduce emissions by up to 75 percent by 2050 compared with 2017. Around 20 percent will come from operational advances, such as energy-efficiency measures and clinker substitution. An additional 10 percent will come from alternative fuels—however, the availability of

Environmental impact of cement production and

2022年1月1日 This stone reviews the impact of cement industry towards the global environment and solutions to the problem. The increasing harvesting of raw materials for mounting cement manufacturing causes reduction in quantity of the non-renewable resources such as limestone. The activities linked to harvesting of the resources from

GCCA Sustainability Guidelines for co-processing fuels

2019年10月28日 These guidelines for co-processing of fuels and raw materials in cement manufacturing are part of a package of guidelines developed to support compliance with the GCCA Sustainability Charter 1. The GCCA Sustainability Charter has identified five key pillars which encompass the sustainability issues for the cement and concrete sector:

Cement Plant an overview ScienceDirect Topics

Fabrizio Bezzo, in Computer Aided Chemical Engineering, 2022 1 Introduction Cement plants, steel mills and refineries are responsible for a significant share of carbon dioxide (CO2) emissions ( EEA, 2020 ), which are among the greenhouse gases responsible for the global threat of climate change.

Analysis of material flow and consumption in cement

2016年1月20日 The results show that approximately 2.48 t, 4.69 t, and 3.41 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages, and their waste rates are 63.31%, 74.12%, and 78.89%, respectively. The recycling rate of wastes during clinker production is remarkably higher

11.6 Portland Cement Manufacturing US EPA

1971年8月17日 The initial production step in portland cement manufacturing is raw materials acquisition.Calcium, the element of highest concentration in portland cement, is obtained from a variety ofcalcareous raw materials, including limestone, chalk, marl, sea shells, aragonite, and an impurelimestone known as "natural cement rock".

Advanced analyses of solid waste raw materials from

2019年4月1日 1. Introduction The Egyptian cement market is known to be one of the biggest in the globe including twenty-one cement producers operate twenty-four plants. The cement industry is one of the most important economic drivers in Egypt's economy. Suez Cement Group of Companies (SCGC) is one of the oldest cement producers in Egypt.

Raw materials for cement manufacturing Cement Plant

Limestone: Common forms of calcium carbonate used as raw material for cement manufacturing are limestone and chalk.Limestone is of predominantly fine grained crystalline structure, its hardness is between 1.8 to 3.0 of the Mohs scale of hardness and specific gravity 2. To 2.8.

Preparation Of Cement Raw Material Cement

The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing. Crushing: the limestone and other materials are crushed into small pieces by cement crusher,

Analysis of material flow and consumption in cement

2016年1月20日 The material flow route for a cement plant was obtained. • Three mass balances for three cement production stages were established. • Each ton of products requires 2.48, 4.69, and 3.41 t of materials in three stages. • Waste gas recycling rate in clinker production is higher than in other stages. •

Digitization and the future of the cement plant McKinsey

2020年9月16日 Today’s cement plant This future is not far off. Our analysis shows that pursuing digitization and sustainability levers are key to significantly boosting productivity and efficiency of a typical cement plant (Exhibit 1).

Clay calcination technology: state-of-the-art review by the

2021年12月20日 LOI is a well-known indicator in cement plants and its use for calcination of clay is direct . The calibration of the LOI on a performance-based approach makes this indicator valuable. The conditions of calcination giving the highest strength can be targeted in terms of LOI. Emissions from transport of the raw materials to the processing

GCCA Sustainability Guidelines for co-processing fuels

2019年10月28日 These guidelines for co-processing of fuels and raw materials in cement manufacturing are part of a package of guidelines developed to support compliance with the GCCA Sustainability Charter 1. The GCCA Sustainability Charter has identified five key pillars which encompass the sustainability issues for the cement and concrete sector:

Analysis of material flow and consumption in cement

2016年1月20日 The results show that approximately 2.48 t, 4.69 t, and 3.41 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages, and their waste rates are 63.31%, 74.12%, and 78.89%, respectively. The recycling rate of wastes during clinker production is remarkably higher

11.6 Portland Cement Manufacturing US EPA

1971年8月17日 The initial production step in portland cement manufacturing is raw materials acquisition.Calcium, the element of highest concentration in portland cement, is obtained from a variety ofcalcareous raw materials, including limestone, chalk, marl, sea shells, aragonite, and an impurelimestone known as "natural cement rock".

Advanced analyses of solid waste raw materials from

2019年4月1日 1. Introduction The Egyptian cement market is known to be one of the biggest in the globe including twenty-one cement producers operate twenty-four plants. The cement industry is one of the most important economic drivers in Egypt's economy. Suez Cement Group of Companies (SCGC) is one of the oldest cement producers in Egypt.

Parametric Studies of Cement Production

The cement manufacturing process starts by handling a mix of raw materials: (i) naturally occurring limestone, which is the source of calcium, (ii) clay minerals and (iii) sand, which are the sources of silicon and